Tubing

So why use SS tubing instead of swaged hoses or CGA fittings?

- SS tubing is relatively cheap

- It can handle high pressures

- The fittings for it are cheaper than NPT equivalents

- The lengths and bends can be customized on the spot

Read

this before installing tubing into fittings and to gain a familiarity with

some options available.

Materials recommendation

SwageLok and many other fittings manufacturers have

great PDF files available that explain materials selection, like

this

one. Following the charts from the PDF, higher-pressure systems will likely need a 0.035

wall-thickness, 1/4", seamless SS tubing, instrumentation-grade preferred.. The (welded) seam type is not as

strong (but usually cheaper), and may still be suitable depending on what

pressures you want to target. 0.035 thick tubing is rated for 5100 PSI and the next

higher-pressure choice is 0.049 at 7500 PSI. For the welded-seam type of tubing, you

have to deduct 15% of those figures for its working pressure.

Buying

A friend of mine was able to

get me 100 feet of 0.035 wall-thickness 1/4" SS tubing, for about $60,

the average wholesale cost. It can come in a roll but you have to

unbend it. I got mine in straight lengths of 20 feet each.

I opted for the straight lengths instead of the coils since I didn't

feel like having to unbend the tubing and then re-bend it. Local

hydraulic and/or plumbing supply shops can usually carry (or can order)

several types of tubing, but normally charge in the neighborhood of

$1-$2 per foot.

Beware of eBay's Dutch-style bidding auctions! They are not too

common, but you will occasionally happen upon them.. The recommended way to bid

on this style of auction is to bid on a single item at a time, for as many as

you want, and steadily increase the price of each successive item's bid.

This stair-steps your price and allows you to win a good majority, if possible,

at an averaged price. Doing this does not raise the price that everyone

else would have to pay who are willing to pay a premium just to buy one item and

have to outbid you. It's always best to leave a few behind for the others

then you can get the remainder at a lower price. For example, I won an

entire lot through one of these auctions, even though I paid about 150% more per

unit in order to win them all of them. Had I only bid on 7 instead of 10,

my price would have been 30% per unit instead of 100%. Nevertheless, I

ended up using all of the items, so it was still a worthwhile deal considering

the trouble of finding more of these in smaller lots and then paying additional

shipping for each lot.

Cleaning

All

the tubing used for this project was oxygen-cleaned. It shouldn't be

necessary for air banks, but wasn't much trouble to do anyway. I use a

submersible ornamental-pond pump to push a 5% solution of

Blue Gold through

pipes, tubes, etc. The pump sits in a bucket of the solution and pumps it

in one end of the tube by means of some fittings, flexible tubing, and hose

clamps. The other end of whatever is being flushed has to be aimed back in

to the bucket. For long straight lengths of tubing, I just made a U-bend

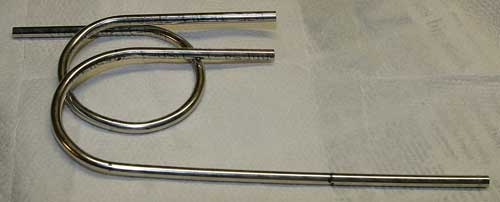

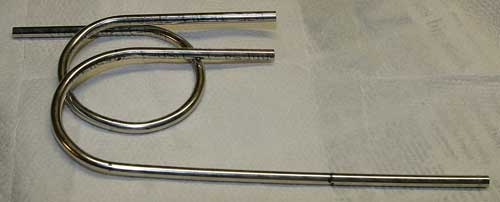

halfway up the pipe. Pictured are a couple inter-stage cooling coils from

a RIX compressor that were getting flushed overnight.

All

the tubing used for this project was oxygen-cleaned. It shouldn't be

necessary for air banks, but wasn't much trouble to do anyway. I use a

submersible ornamental-pond pump to push a 5% solution of

Blue Gold through

pipes, tubes, etc. The pump sits in a bucket of the solution and pumps it

in one end of the tube by means of some fittings, flexible tubing, and hose

clamps. The other end of whatever is being flushed has to be aimed back in

to the bucket. For long straight lengths of tubing, I just made a U-bend

halfway up the pipe. Pictured are a couple inter-stage cooling coils from

a RIX compressor that were getting flushed overnight.

Tubing can be air-blasted dry with compressed SCUBA air. This helped

get rid of sediments or other ambient impurities that happen to be suspended in

the rinse water, instead of allowing it to deposit onto the metal when the water

evaporates. To do the air blast, a

tube/NPT fitting

can be used on the tube. The fitting only needs about an1/8-1/4 turn past

finger-tight so the ferrules have a friction-bite but but not enough to indent the tubing

like a permanent swage. If you use this method, be careful with the amount of

air pressure you force through the tube or the tube could shoot loose from its

fitting.

Cutting

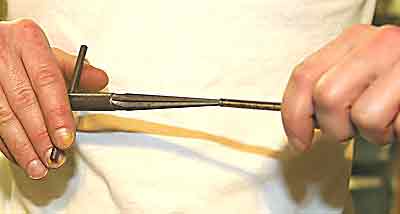

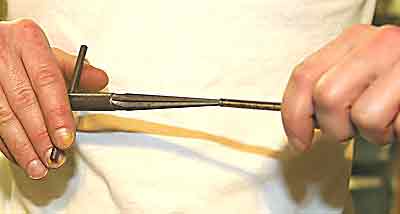

To cut tubing, I used a pipe-cutting clamp as seen in this picture.

You can always use a hacksaw to cut the tubing, and

post-prep the tube end in the same way. The

clamp cutter works by just spinning it around the tubing and occasionally adding

a light twist of the screw to push the cutting-wheel deeper when it starts to spins freely. Eventually

the cutter presses a clean, right-angle cut into the pipe until the two halves break

free. This process leaves lip inside the pipe that has to be gently reamed out.

You can always use a hacksaw to cut the tubing, and

post-prep the tube end in the same way. The

clamp cutter works by just spinning it around the tubing and occasionally adding

a light twist of the screw to push the cutting-wheel deeper when it starts to spins freely. Eventually

the cutter presses a clean, right-angle cut into the pipe until the two halves break

free. This process leaves lip inside the pipe that has to be gently reamed out.

If you hacksaw the pipe, make sure that the blade does NOT chatter itself out of

the cut path and along the top of the tube. It WILL leave marks on the tubing

surface. If these marks get in the ferrule's sealing area, this can cause

it to fail sealing under high pressures. Even the normal "coining" that the ferrule

does t o the tubing during swaging may not be enough to draw these mars out, so don't depend on

that. The ferrule ends about 3/8-1/4" from the the tip of the tube, which

leaves a little breathing space for blunders of this sort. But if you get close

to or exceed that, just move your cut on top of mark furthest back and begin the

cut there, if you have enough spare tubing length, which is normally always a

good idea.

Dressing the cut

I used this tool to ream with (O2-cleaned of course!)

Alternatively, a drill bit could be carefully used as a reamer, but just enough

to begin an internal chamfer. I run a metal file across the cut to de-burr any

artifacts left from the reaming, and then file a tiny chamfer around the

outside edge of the tube. After all this, I wash the outside of the tube with Blue Gold

and rinse it carefully, trying not to let any fluid wick its way up inside the

tube via surface

tension. I try to get the tubing in place and locked down quickly after cleaning

to prevent as much ambient dust as possible from getting on the end.

Tube routing

To make the longer tubing runs, I usually took a wooden folding ruler and tried

to bend it around in the same shapes I wanted to run the tubing.

This

measurement doesn't have to be too exact, because longer runs with bends and elbows

allow for stretching or shrinking to adjust for small under/over-sized length issues.

Allow for an extra 2-5% length on the longer runs. Discarding long runs because they are just too

short is not worth sacrificing a bit of cheap tubing over to get it fitted

correctly in the first place. For shorter

runs, I made a habit of allowing allow a little extra length (10%) to allow for

additional fitting flexibility. Cut off any excess if it's going to just

get in the way. Also allow about 1-2"

for the final bends into the fitting. SwageLok and others recommend 13/16" of

perfectly straight section where the tube is inserted into the fitting, next to

where a usual bend might need to be located. See

their

PDF for more information on this. Armed with a measurement, cut a piece of tubing off the base stock.

This

measurement doesn't have to be too exact, because longer runs with bends and elbows

allow for stretching or shrinking to adjust for small under/over-sized length issues.

Allow for an extra 2-5% length on the longer runs. Discarding long runs because they are just too

short is not worth sacrificing a bit of cheap tubing over to get it fitted

correctly in the first place. For shorter

runs, I made a habit of allowing allow a little extra length (10%) to allow for

additional fitting flexibility. Cut off any excess if it's going to just

get in the way. Also allow about 1-2"

for the final bends into the fitting. SwageLok and others recommend 13/16" of

perfectly straight section where the tube is inserted into the fitting, next to

where a usual bend might need to be located. See

their

PDF for more information on this. Armed with a measurement, cut a piece of tubing off the base stock.

Next, the tube had to be bent into its final

shape. I sometimes used my bare hands to bend tubing, but in order to prevent

the tubing from collapsing into a weakened, ovular, shape, a tube-bending tool

is recommended, especially for short bends. Pictured at the left is one I

picked up from

Harbor Freight for $7

I would sometimes have to place one end of the fresh-cut tube end in its target fitting to

figure out where the bends had to be. If you cut your tubing with a hack-saw,

de-burr the outside corner of the cut with a metal file to prevent the normal

metal burrs from scratching the sealing-surface inside the lower ferrule before

the initial fitting. If using a clamp-cutter, the cut-end is usually rounded off, but I

have seen a lip on the outside edge before and deserves careful attention as

well. It sometimes happens when greater pressure is used with the

clamp-cutter. Also, putting the tube in and

out of the fitting can introduce dust or other contaminants onto the ferrules

that might reduce their sealing efficiency. Keep everything as clean as

possible! After temporarily placing one tube end in its fitting, use a marker to mark

the spot(s) off where the next bend(s) should be. Remove the tube out

of the one fitting, make the bend(s), and put it back for another test-fit and

marking. I recommend making one bend at a time between testing when runs

have more than one acute or obtuse angle. Repeat the fitting and bending

until the tube looks just about right. There should be little need to

insert the second tube-end in its fitting.

Making

the tubing pigtails were difficult to work with since the bottles were not all identically

the exact same distance (or alignment) between the fittings. This required me to

stretch some pigtails out and compress others. The pigtails with the smallest

loops took more effort and was a good argument to use larger (3"-5") loops. This

is another good reason not to make the tails too small!

Making

the tubing pigtails were difficult to work with since the bottles were not all identically

the exact same distance (or alignment) between the fittings. This required me to

stretch some pigtails out and compress others. The pigtails with the smallest

loops took more effort and was a good argument to use larger (3"-5") loops. This

is another good reason not to make the tails too small!

In the picture to the left, I cut out a 15" length and divided it into

sections and marked them as a reference guide to use when bending. A

completed pigtail is also nice to have as a reference. Generally, for the

pigtails, it was best to spin the cylinders a couple degrees from each other so

that the tube fitting on each matched the normal lateral offset of the pigtail's

ends. You can see the offset in the completed pigtail in the picture. Otherwise, the pigtail

ends have to bent laterally together so that the tube ends'

centers are perfectly aligned. This method is not recommended since you risk

putting a bit of stress on the ferrules.

Next, I would bend half the pigtail, then bend the rest of it. This

helped keep the loop symmetrical since the bending tool is not a precision

instrument and takes some

getting-used

to make bends exactly the way you want.

getting-used

to make bends exactly the way you want.

Connections

After getting the the tube bent correctly and ready to be locked in place,

remove it, perform a final dressing on the ends if it has not been done already,

and clean the ends as noted previously.

A properly-swaged ferrule will look like the following picture .

Notice how the lower ferrule bends the tube inwards as the nut is tightened, to

create a swaged-fit. The white specs are ambient dust!

.

Notice how the lower ferrule bends the tube inwards as the nut is tightened, to

create a swaged-fit. The white specs are ambient dust!

I wasted about 5 sets of

ferrules from mistakes during tube-assembly, learning things the hard way like cutting pieces just

slightly too short, etc. I recommend having a few extra sets of ferrules handy

for these sorts of learning experiences. You may even have ferrules that

you can swipe from excess fittings.

The tube end should be perfectly straight for 13/16" of an inch, and free of

any marring/ marks. This requires some care when handling the tubing. If a

tube-end has even a slight bend in it less than 13/16" from the tip, it may

not seal as well as you would like. If in doubt, cut it off and start over. These bends can cause binding on the ferrules

and prevent the tube from seating all the way in, which can lead to a

dangerously-weakened swage. The picture below (right-side ferrule) shows a

possible example of the tube getting pulled out of the ferrule before the nut

was was locked down.

Insert the tubes as straight as possible into the fitting nut. It should go in

very easy and even have some play. You should not have loosen the nut to allow

the tube to be inserted to its full depth. If the tube won't go in all the way,

remove the tube and add a slight bend (by hand if possible) beyond the 13/16"

minimum distance in order to get the alignment

of the tube and fitting more exact. This is another reason why it is good to have

some extra slack in the tube length or at least two bends in the route.

Make sure the tubing bottoms out in the fitting!

When wrestling with some short runs that were not lining up easily I sometimes found that I was pulling the

opposite end out of one

fitting while trying to put the the other end in its fitting or getting the tubing bent just right

in order to do so. This sometimes required me to lock one end of the tube

in place and then wrestle with the

free end. Doing this puts stress on, and could bend/loosen, the already-tightened end. This is

NOT recommended! Doing this may cause a tube to begin bending too close to the secured

nut, and actually have the effect of a crowbar pulling the tubing through

the swaged ferrule if enough force is applied, not to mention loosening the seal

between the ferrule and fitting. The ferrule on the left in this picture

is conically warped to one side because of this. Also note that its

outside sealing surface has been strained and is not longer very smooth for a

high-quality seal.

When wrestling with some short runs that were not lining up easily I sometimes found that I was pulling the

opposite end out of one

fitting while trying to put the the other end in its fitting or getting the tubing bent just right

in order to do so. This sometimes required me to lock one end of the tube

in place and then wrestle with the

free end. Doing this puts stress on, and could bend/loosen, the already-tightened end. This is

NOT recommended! Doing this may cause a tube to begin bending too close to the secured

nut, and actually have the effect of a crowbar pulling the tubing through

the swaged ferrule if enough force is applied, not to mention loosening the seal

between the ferrule and fitting. The ferrule on the left in this picture

is conically warped to one side because of this. Also note that its

outside sealing surface has been strained and is not longer very smooth for a

high-quality seal.

Before locking a ferrule-nut down, make sure it is finger-tight, as it should

have been before inserting the tubing. The tubing should be fully bottomed out

in the fitting. Don't rely on feel alone to determine this - I have had some

ends that only made it to the bottom of the lower ferrule when the tube was

under a little stress from its position and wouldn't allow it to seat all the

way. The ferrule on the right in the picture is an example of what could

happen. If you aren't completely sure if the tube is bottomed out or not,

pull the tube back out and put a mark on the exposed section of tube, about

where it should contact the nut but still be visible and use this as a visual

reference point to determine how far the tube has gone into the fitting. If the

ferrule has not swaged itself high enough onto the tube, the tube could actually

blow the tube right out of the fitting.

Next, scribe or use a marker to mark a point on the nut's surface.

The mark can either pointing

up, down, or 90' from there. The nut gets turned one and one quarter turns,

exactly. The mark is just a reference as to where the start-point was at. This tightening only

applies to the initial swage. If you have to take the tube loose and tighten it

again, the nut has to go further than it did initially until just after "the

resistance builds up quickly" Refer to the SwageLok PDF previously mentioned, as

it has all this information written there. SwageLok has a nut-to-fitting

gap-measurement tool when in doubt. Be aware that you can only re-tighten

the fittings so many times before the ferrule is narrowed/mashed down too far

to seal on the fitting's flare.

GO TO PAGE:

1 - Introduction

2 - Bank Bottles

3 - Fittings 5 -

Valves 6 - Manifolds,

whips, gauges,O2-cleaning 7

- Results & Pictures

All

the tubing used for this project was oxygen-cleaned. It shouldn't be

necessary for air banks, but wasn't much trouble to do anyway. I use a

submersible ornamental-pond pump to push a 5% solution of

Blue Gold through

pipes, tubes, etc. The pump sits in a bucket of the solution and pumps it

in one end of the tube by means of some fittings, flexible tubing, and hose

clamps. The other end of whatever is being flushed has to be aimed back in

to the bucket. For long straight lengths of tubing, I just made a U-bend

halfway up the pipe. Pictured are a couple inter-stage cooling coils from

a RIX compressor that were getting flushed overnight.

All

the tubing used for this project was oxygen-cleaned. It shouldn't be

necessary for air banks, but wasn't much trouble to do anyway. I use a

submersible ornamental-pond pump to push a 5% solution of

Blue Gold through

pipes, tubes, etc. The pump sits in a bucket of the solution and pumps it

in one end of the tube by means of some fittings, flexible tubing, and hose

clamps. The other end of whatever is being flushed has to be aimed back in

to the bucket. For long straight lengths of tubing, I just made a U-bend

halfway up the pipe. Pictured are a couple inter-stage cooling coils from

a RIX compressor that were getting flushed overnight.

When wrestling with some short runs that were not lining up easily I sometimes found that I was pulling the

opposite end out of one

fitting while trying to put the the other end in its fitting or getting the tubing bent just right

in order to do so. This sometimes required me to lock one end of the tube

in place and then wrestle with the

free end. Doing this puts stress on, and could bend/loosen, the already-tightened end. This is

NOT recommended! Doing this may cause a tube to begin bending too close to the secured

nut, and actually have the effect of a crowbar pulling the tubing through

the swaged ferrule if enough force is applied, not to mention loosening the seal

between the ferrule and fitting. The ferrule on the left in this picture

is conically warped to one side because of this. Also note that its

outside sealing surface has been strained and is not longer very smooth for a

high-quality seal.

When wrestling with some short runs that were not lining up easily I sometimes found that I was pulling the

opposite end out of one

fitting while trying to put the the other end in its fitting or getting the tubing bent just right

in order to do so. This sometimes required me to lock one end of the tube

in place and then wrestle with the

free end. Doing this puts stress on, and could bend/loosen, the already-tightened end. This is

NOT recommended! Doing this may cause a tube to begin bending too close to the secured

nut, and actually have the effect of a crowbar pulling the tubing through

the swaged ferrule if enough force is applied, not to mention loosening the seal

between the ferrule and fitting. The ferrule on the left in this picture

is conically warped to one side because of this. Also note that its

outside sealing surface has been strained and is not longer very smooth for a

high-quality seal.