Manifolds

A manifold provides for a solid, central mounting point for valves, whips,

gauges, and other fittings. The same functionality could be accomplished

by the use of tees, but that gets expensive as the number of attachments grow.

Be aware that the constant twisting of valves, pulling on whip hoses, and other

stresses will bend, torque, and put a lot of strain on the tubing and/or

fittings. Although there is no front panel (1/4-3/16" PlexiGlass might

suit) to secure the ball-valve stems in place (on the 4 air-bank lines), this

will be a near-future addition to the project.

The

manifolds I was

originally looking

to use are resold by Global:

They have a 45386

and version 45388 which is the same, only oxygen-cleaned.. They are made of brass

and suitable for 4500+ PSI. The oxygen-cleaned version costs around $145. I've seen these. used in dive shops and the

wider spacing between the ports is better for screwing fittings and valves into

it that are not straight and narrow. It also points the whips out at 120

degrees, away from the wall and

towards your bottles, eliminating some bend in fill-whip hoses.

The

manifolds I was

originally looking

to use are resold by Global:

They have a 45386

and version 45388 which is the same, only oxygen-cleaned.. They are made of brass

and suitable for 4500+ PSI. The oxygen-cleaned version costs around $145. I've seen these. used in dive shops and the

wider spacing between the ports is better for screwing fittings and valves into

it that are not straight and narrow. It also points the whips out at 120

degrees, away from the wall and

towards your bottles, eliminating some bend in fill-whip hoses.

I ended up with a better deal on

a different manifold configuration.

Superior Products makes a GMA-SCMB

6-port manifold, cleaned for oxygen-use right from

the factory, and rated for 4500 PSI. These manifolds can be found for

about $25 each. I bought three of these which gave me twenty 1/4" NPT

ports, at half the cost of the Global

manifold with 10 ports. However, the cost balances out a little further

because each end of the SP manifolds required 1/2" reducer bushings

(see picture to the right) for the 1/2" NPT fittings I wanted to use for

everything. (See the brass fittings above) Also, the ports are nearly on

2.5" centers, which restricts which fittings can be screwed in to which ports.

I connected two of these end-to-end to make one long manifold

I ended up with a better deal on

a different manifold configuration.

Superior Products makes a GMA-SCMB

6-port manifold, cleaned for oxygen-use right from

the factory, and rated for 4500 PSI. These manifolds can be found for

about $25 each. I bought three of these which gave me twenty 1/4" NPT

ports, at half the cost of the Global

manifold with 10 ports. However, the cost balances out a little further

because each end of the SP manifolds required 1/2" reducer bushings

(see picture to the right) for the 1/2" NPT fittings I wanted to use for

everything. (See the brass fittings above) Also, the ports are nearly on

2.5" centers, which restricts which fittings can be screwed in to which ports.

I connected two of these end-to-end to make one long manifold

CGA (347) Nuts and nipples

Generally,

these are all made by

Western Enterprises,

and have to be ordered through a dealer. The nipple

ends are always 1/4" MNPT, so they are relatively easy to find FNPT fittings

to attach with.

Here's an example of the nut and nipple and how they were mated with the other

parts for connecting the banks. The

brass versions for these parts are rated to CGA-347 pressure

standards (<5000 PSI) and are safer in an oxygen environment as a bonus.

My local gas

supplier charged me about $13 per pair (nut and nipple) for my first 10 sets.

When I got my second set of bottles, I bought an additional 14 at nut: $3.94 per

nut and $5.77 per nipple, so it pays off to to hunt around for better pricing.

Generally,

these are all made by

Western Enterprises,

and have to be ordered through a dealer. The nipple

ends are always 1/4" MNPT, so they are relatively easy to find FNPT fittings

to attach with.

Here's an example of the nut and nipple and how they were mated with the other

parts for connecting the banks. The

brass versions for these parts are rated to CGA-347 pressure

standards (<5000 PSI) and are safer in an oxygen environment as a bonus.

My local gas

supplier charged me about $13 per pair (nut and nipple) for my first 10 sets.

When I got my second set of bottles, I bought an additional 14 at nut: $3.94 per

nut and $5.77 per nipple, so it pays off to to hunt around for better pricing.

If you have a bottle that

will not be permanently connected, there is a hand-tightening version to

make attaching/detaching faster. The nut can come with a handwheel for

leverage, and the nipple has a nylon/teflon-o-ring inset into the nipple tip for

a positive seal. The ones at the left are what you would find for

lower-pressure CGA fittings: the CGA 347 hand-tightened nut is more compact.

If you have a bottle that

will not be permanently connected, there is a hand-tightening version to

make attaching/detaching faster. The nut can come with a handwheel for

leverage, and the nipple has a nylon/teflon-o-ring inset into the nipple tip for

a positive seal. The ones at the left are what you would find for

lower-pressure CGA fittings: the CGA 347 hand-tightened nut is more compact.

O2-cleaning

Once again, if you haven't read it yet, please read the

Oxyhacker's Companion

to get a good handle on this very-important subject. Oxygen cleaning is one thing

not to overlook if you plan on having plumbing that will experience high FO2's.

Although some fittings in this document were only going to be subjected to air

(for the time being), they were oxygen-cleaned anyway. Every fitting in

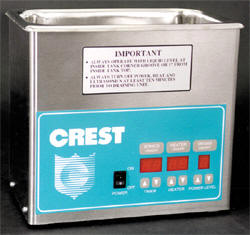

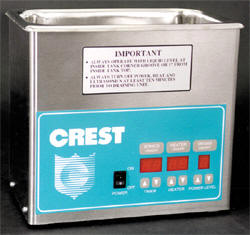

this document was completely disassembled and cleaned in an ultrasonic cleaner. The cleaner used is pictured (without a mandatory SS mesh basket) and has a

3-quart capacity, which is perfect to fit a couple valves or all the parts of a

tank manifold into at one time. This one can be had

for under $400 if you

shop around. For fittings where there is no danger of surfaces getting

marked-up or damaged through

vibration and close proximity, I set the cleaner on highest power (9). The

temperature was normally set for 145-degrees F and the run-time set for 90

minutes.

The cleaner used is pictured (without a mandatory SS mesh basket) and has a

3-quart capacity, which is perfect to fit a couple valves or all the parts of a

tank manifold into at one time. This one can be had

for under $400 if you

shop around. For fittings where there is no danger of surfaces getting

marked-up or damaged through

vibration and close proximity, I set the cleaner on highest power (9). The

temperature was normally set for 145-degrees F and the run-time set for 90

minutes.

For

cleaning fluid, a 5% solution of

Blue Gold detergent,

is commonly accepted as being an effective, safe, and common ultrasonic fluid

for oxygen-cleaning in the SCUBA industry. This detergent can put Simple

Green to shame on heavy grease, even when cold. A 5-gallon pail of Blue

Gold will last several years of activity, and can make 100 gallons of fluid or

133 refills for my 3-quart ultrasonic. These pails used to cost around $60

delivered to your door from the manufacturer when I bought this one. The

prices have really gone up now. You can buy it in smaller quantities from some

on-line SCUBA-supply shops. Even though you can re-use the same bath many

times over, oxygen-cleaning for high-pressure applications deserves some more

caution and respect. I typically dispose of a bath after cleaning parts

with even small amounts of oil or grease. A fresh bath was obviously

needed after cleaning the graph-oiled ball-valve parts. One strategy is to

run all of the really dirty pieces through the same bath just to get the gross

contamination off the surfaces. After discarding the bath, and rinsing the

parts off in fresh water, everything

can run through a second, clean, ultrasonic bath.

For

cleaning fluid, a 5% solution of

Blue Gold detergent,

is commonly accepted as being an effective, safe, and common ultrasonic fluid

for oxygen-cleaning in the SCUBA industry. This detergent can put Simple

Green to shame on heavy grease, even when cold. A 5-gallon pail of Blue

Gold will last several years of activity, and can make 100 gallons of fluid or

133 refills for my 3-quart ultrasonic. These pails used to cost around $60

delivered to your door from the manufacturer when I bought this one. The

prices have really gone up now. You can buy it in smaller quantities from some

on-line SCUBA-supply shops. Even though you can re-use the same bath many

times over, oxygen-cleaning for high-pressure applications deserves some more

caution and respect. I typically dispose of a bath after cleaning parts

with even small amounts of oil or grease. A fresh bath was obviously

needed after cleaning the graph-oiled ball-valve parts. One strategy is to

run all of the really dirty pieces through the same bath just to get the gross

contamination off the surfaces. After discarding the bath, and rinsing the

parts off in fresh water, everything

can run through a second, clean, ultrasonic bath.

Be warned that there are some parts that high-power cleaning levels

can damage. Many ultrasonic cleaners can completely chew up a piece of

aluminum foil into dust. I have seen the cavitation alone leave permanent

wear marks on chrome valves. The highest setting on mine removed some of the silver electroplated

silver from the

insides of tube nuts. You do not want ferrules to vibrate against each other

and cause marks on the sealing surfaces.. Lower-power settings and/or

reduced run-times are prudent for some jobs. Often, after cleaning parts that

have oxygen-compatible greases on them, the lubricant's base (teflon/PTFE, etc)

will clump up and float on the surface of the cleaner after the lubricant's

carrier (fluid part) is dissolved into the bath.

Some parts

to be cleaned are so small that they would normally fall through the usual wire mesh

basket that holds everything away from the surfaces of the cleaner. A

finer tray for these can be made out of a a plastic container with a screw-on

lid similar to peanut-butter jar lid shown here. The only parts needed

are the threaded rims of the container and lid, and a piece of cloth screen.

Simply sandwich the screen between the two parts, screw them together, and trim

off the excess screen.

Some parts

to be cleaned are so small that they would normally fall through the usual wire mesh

basket that holds everything away from the surfaces of the cleaner. A

finer tray for these can be made out of a a plastic container with a screw-on

lid similar to peanut-butter jar lid shown here. The only parts needed

are the threaded rims of the container and lid, and a piece of cloth screen.

Simply sandwich the screen between the two parts, screw them together, and trim

off the excess screen.

Alternately, there are other acceptable methods of oxygen-cleaning, some as

simple as using ivory dish soap, a plastic container, and manual agitation.

For more ideas, read the

Oxyhacker's Companion.

When re-assembling parts that

require lubrication, Christo-lube MCG-111 (for moving parts),

Christo-lube MCG-129

(for static parts),

DuPont Krytox and several other appropriate oxygen-compatible lubricants

should be used.

Whip fittings

I

am partial to Sherwood's right-angle DIN fill-whip ends (as shown to

the left) due to the fact that it reduces fiddling with a stiff, bend-resistant

hose in order to line the whip up just right to get the threads started.

The 90-degree fittings are much faster/easier to line up and screw in place

since they swivel. See the picture below for comparison.

I

am partial to Sherwood's right-angle DIN fill-whip ends (as shown to

the left) due to the fact that it reduces fiddling with a stiff, bend-resistant

hose in order to line the whip up just right to get the threads started.

The 90-degree fittings are much faster/easier to line up and screw in place

since they swivel. See the picture below for comparison.

These fittings can be bought for

less than $50 each and have a 1/4" FNPT connection.. A retailer for these told me he replaces the hidden o-ring (where the DIN

fitting screws into the body) with an oxygen-compatible one, but the rest of the

unit comes

O2-ready right from Sherwood. These units normally come with a silicone

DIN o-ring, however I swap mine out for Viton or EPDM versions, just for

O2-safety.

You will notice Parker QD's connecting the whip hoses

(click on the picture to the right for a closer look) and other attachments

(like the digital pressure gauge). My preference is to use male connectors

on all hose-ends and female QD's on everything else

Whip hoses

Your local hydraulic hose shop can have whips made up for

you of breathing air hose. Although regular hydraulic hose could be used,

industry officials frown on this for fear of chemicals leaking from the hose as

it wear/degrades over time in addition to erosion. When dealing with

oxygen, the difference in cost is at least worth peace of mind. The hoses

shown in the pictures were made at my favorite local

hose/supply shop. Even better, they also stock a tremendous amount of SS high-pressure and instrumentation-tubing

fittings. These whips are made from Saint Gobain's Synflex 3R80-4, which runs about

$2.57 per foot, just for the hose. The hose falls under SAE100R8 specs, has a 5000 PSI working pressure,

and 1/4" internal diameter. A company rep for the manufacturer said that they'll allow them for

oxygen service up to 3,000 PSI. Parker also makes a similar hose for

breathing gases.

The fittings you have to get swaged on to the hose can get

expensive. 1/4" NPT is the preferred choice of fitting for the hoses,

since it makes it handy to screw into just about anything. 6' lengths are

a good starting size unless you want to fill your bottles a little distance from

the manifold. All of the non-tube plumbing shown in the pictures was designed around

the NPT

thread and 1/4" size. A couple of the hoses shown above have swaged

stainless-steel fittings which cost almost $40 per fitting. Very few people will want to pay $90 for six-foot fill

whip, but they are suitable for high-pressure oxygen-use on the output side of a

Haskel.

The hoses connected to the air manifold have zinc-plated

carbon-steel fittings, which is suitable for air and nitrox mixes under the

proverbial 40% limit, with appropriate cleaning. At $16.25 for a complete

6' hose with fittings, the cost is fairly reasonable. The steel fittings now have

a tinge of some rust forming on them, (especially after

the O2-cleaning) which is a good reason to appreciate SS versions.

O2-cleaning hoses is recommended. Hose fittings are usually swaged on with mineral oil or some grease

to keep the hose from grabbing or binding up as the fittings is initially shoved

over the end of the hose for swaging. All the hoses used are

oxygen-cleaned as best as can be expected (refer to the section on O2-cleaning),

to reduce any swaging contaminants that might be lurking inside the hose.

This isn't a guarantee of safety, but every little bit reduces the risk factor.

The Parker quick-disconnects on all the hoses and whip parts

lend themselves to unusual configurations when needed. A couple

of QD gender-benders (male to male, and female to female) help even

further if needed to accomplish usually-temporary situations when parts

selection is limited. They are especially handy for the

digital pressure gauge shown above when it needs to be moved

around.

Pressure gauges

One of the cheapest places I've found gauges is at

Surplus Center. I bought 2.5" face, dry, 1/4" MNPT, bottom-mount

gauges for each bank. For O2-mixing, larger-faced (>3.5") gauges are

preferred for the precision. For the money, a digital pressure gauge is

quite handy and takes out all the guess-work otherwise left up to squinting

eyes. Surplus Center occasionally has digital pressure gauges for

around $100.

One of the cheapest places I've found gauges is at

Surplus Center. I bought 2.5" face, dry, 1/4" MNPT, bottom-mount

gauges for each bank. For O2-mixing, larger-faced (>3.5") gauges are

preferred for the precision. For the money, a digital pressure gauge is

quite handy and takes out all the guess-work otherwise left up to squinting

eyes. Surplus Center occasionally has digital pressure gauges for

around $100.  McMaster-Carr also carries

one for about

$120. Several can be found from time to time on eBay for even less. I

prefer the doubled accuracy of the Dwyer brand of

digital gauges, despite their higher (~$200) MSRP cost. In a pinch, an air-integrated computer can work as a

digital gauge. Although the manufacturer may have grave misgivings about

using the device for mixes in excess of 40% oxygen, a hydraulic fitting can be

used to convert the from a HP-port threads to 1/4" NPT.

McMaster-Carr also carries

one for about

$120. Several can be found from time to time on eBay for even less. I

prefer the doubled accuracy of the Dwyer brand of

digital gauges, despite their higher (~$200) MSRP cost. In a pinch, an air-integrated computer can work as a

digital gauge. Although the manufacturer may have grave misgivings about

using the device for mixes in excess of 40% oxygen, a hydraulic fitting can be

used to convert the from a HP-port threads to 1/4" NPT.

When choosing a pressure range for this type of

gauge, conventional practice is that the gauge should measure twice the highest

working pressure of the gases which it is to measure. However, the closer the

working pressure is to the gauge's range, the more visual precision it offers

across the range. It's good practice to leave AT LEAST a 20-30% difference

between the working pressure and the gauge's maximum value. Wet

(liquid-filled) gauges are more expensive and not recommended for use at

elevated oxygen levels, due to unnoticed contamination issues if they should

ever leak.

Wet gauges may be appropriate where exposed to vibration through a line

connected to a compressor.

O2-cleaning gauges

Oxygen-cleaning a gauge can be difficult to do,

beyond carefully cleaning the brass NPT threads off.

This thread on

a respected message board offers some opinions on cleaning. Some people

advocate buying old oxygen welding regulators and stripping the high-pressure

gauge off of them, which is designed for oxygen service. However, these

gauges may not read much above 3000 PSI.

I keep a moisture monitor next to the fill panel for a sanity check, although

they will not change indication very quickly. 10%/20%/30% indicator cards

can be found separately from

Texas Technologies. Ask for a sample, or else you may have to buy 10

just to obtain one!

|

In-line moisture indicator housing MSRP? eBay store: 1 for

$70. They can probably be had for $35. |

GO TO PAGE:

1 - Introduction

2 - Bank Bottles

3 - Fittings 4

- Tubing 5 - Valves

7 - Results & Pictures

The

manifolds I was

originally looking

to use are resold by Global:

They have a 45386

and version 45388 which is the same, only oxygen-cleaned.. They are made of brass

and suitable for 4500+ PSI. The oxygen-cleaned version costs around $145. I've seen these. used in dive shops and the

wider spacing between the ports is better for screwing fittings and valves into

it that are not straight and narrow. It also points the whips out at 120

degrees, away from the wall and

towards your bottles, eliminating some bend in fill-whip hoses.

The

manifolds I was

originally looking

to use are resold by Global:

They have a 45386

and version 45388 which is the same, only oxygen-cleaned.. They are made of brass

and suitable for 4500+ PSI. The oxygen-cleaned version costs around $145. I've seen these. used in dive shops and the

wider spacing between the ports is better for screwing fittings and valves into

it that are not straight and narrow. It also points the whips out at 120

degrees, away from the wall and

towards your bottles, eliminating some bend in fill-whip hoses. I ended up with a better deal on

a different manifold configuration.

Superior Products makes a GMA-SCMB

6-port manifold, cleaned for oxygen-use right from

the factory, and rated for 4500 PSI. These manifolds can be found for

about $25 each. I bought three of these which gave me twenty 1/4" NPT

ports, at half the cost of the Global

manifold with 10 ports. However, the cost balances out a little further

because each end of the SP manifolds required 1/2" reducer bushings

(see picture to the right) for the 1/2" NPT fittings I wanted to use for

everything. (See the brass fittings above) Also, the ports are nearly on

2.5" centers, which restricts which fittings can be screwed in to which ports.

I connected two of these end-to-end to make one long manifold

I ended up with a better deal on

a different manifold configuration.

Superior Products makes a GMA-SCMB

6-port manifold, cleaned for oxygen-use right from

the factory, and rated for 4500 PSI. These manifolds can be found for

about $25 each. I bought three of these which gave me twenty 1/4" NPT

ports, at half the cost of the Global

manifold with 10 ports. However, the cost balances out a little further

because each end of the SP manifolds required 1/2" reducer bushings

(see picture to the right) for the 1/2" NPT fittings I wanted to use for

everything. (See the brass fittings above) Also, the ports are nearly on

2.5" centers, which restricts which fittings can be screwed in to which ports.

I connected two of these end-to-end to make one long manifold

If you have a bottle that

will not be permanently connected, there is a hand-tightening version to

make attaching/detaching faster. The nut can come with a handwheel for

leverage, and the nipple has a nylon/teflon-o-ring inset into the nipple tip for

a positive seal. The ones at the left are what you would find for

lower-pressure CGA fittings: the CGA 347 hand-tightened nut is more compact.

If you have a bottle that

will not be permanently connected, there is a hand-tightening version to

make attaching/detaching faster. The nut can come with a handwheel for

leverage, and the nipple has a nylon/teflon-o-ring inset into the nipple tip for

a positive seal. The ones at the left are what you would find for

lower-pressure CGA fittings: the CGA 347 hand-tightened nut is more compact. The cleaner used is pictured (without a mandatory SS mesh basket) and has a

3-quart capacity, which is perfect to fit a couple valves or all the parts of a

tank manifold into at one time. This one can be had

The cleaner used is pictured (without a mandatory SS mesh basket) and has a

3-quart capacity, which is perfect to fit a couple valves or all the parts of a

tank manifold into at one time. This one can be had

Some parts

to be cleaned are so small that they would normally fall through the usual wire mesh

basket that holds everything away from the surfaces of the cleaner. A

finer tray for these can be made out of a a plastic container with a screw-on

lid similar to peanut-butter jar lid shown here. The only parts needed

are the threaded rims of the container and lid, and a piece of cloth screen.

Simply sandwich the screen between the two parts, screw them together, and trim

off the excess screen.

Some parts

to be cleaned are so small that they would normally fall through the usual wire mesh

basket that holds everything away from the surfaces of the cleaner. A

finer tray for these can be made out of a a plastic container with a screw-on

lid similar to peanut-butter jar lid shown here. The only parts needed

are the threaded rims of the container and lid, and a piece of cloth screen.

Simply sandwich the screen between the two parts, screw them together, and trim

off the excess screen.

One of the cheapest places I've found gauges is at

One of the cheapest places I've found gauges is at

McMaster-Carr also carries

McMaster-Carr also carries